很荣幸获得了RA生态工作室举办的RA4M2-SENSOR开发板评测活动,板子已经收到,由于我用不惯官方的IDE,所以评测都是以Keil为主。

本次进行任务1中的Analogue和Timers两部分的综合测试,电容式触摸感应单元(CTSU)功能在e2stduio上可以正常运行,keil上无法正常运行,问题还没有找到,解决了后续会分享相关测试。

板载资源介绍如下:

1.两个 USB 全速 2.0 主机(Type-C 连接器)

2.两种烧录方式

SWD 烧录口:编程或调试 PC

串口烧录:打印数据或烧录

3.用户指示灯和按钮

三个用户指示灯(红色和黄色

两个串口指示灯(红色)指示调试连接

两个电源指示灯(红色)

三个用户按键, 一个复位按键

4.外部晶振

低速晶振: 32.768KHz

高速晶振: 12MHz

5.生态系统扩展

微控制器全部引脚由 CN3、 CN4、 CN7、 CN8 引出

传感器(SENSOR)系列 扩展连接器

这次虽然只是进行Analogue和Timers两部分的综合测试,但是板载的LED、按钮、Uart一个不漏也全部测试一遍。

项目创建过程就不再赘述了,网上的教程多如牛毛,数不胜数。下面我们直接进行所有资源配置的相关介绍。

板载的LED、按钮、Uart的原理图如下:

根据原理图上的引脚定义进行配置,

1.按键配置如下:

2.uart配置如下:

3.led配置如下:

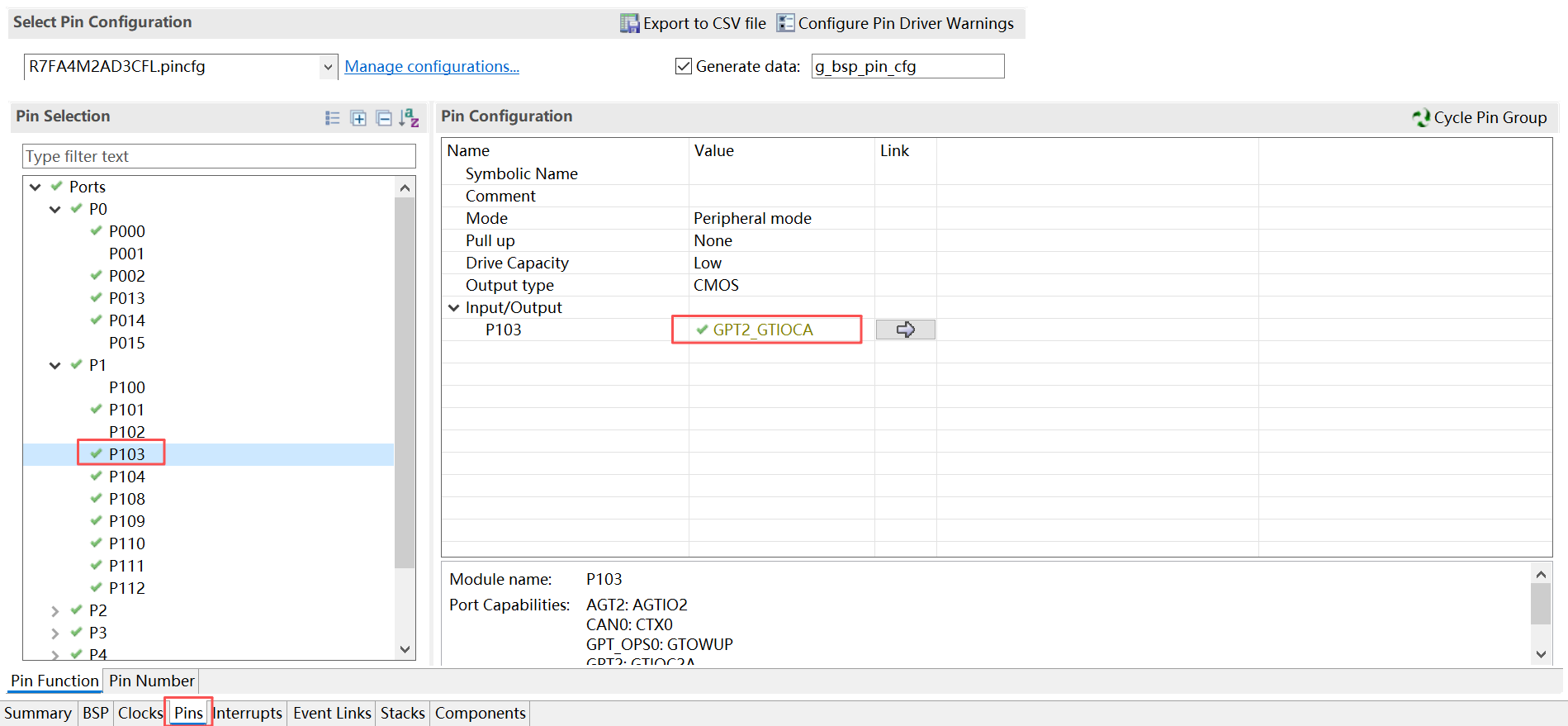

D3通过PWM控制,所以配置有所不同,如下:

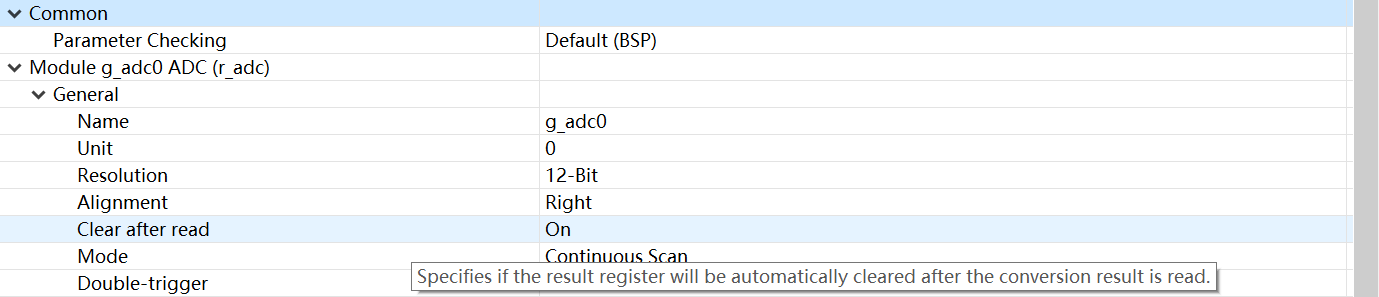

4.ADC(只启用通道0)软件触发、连续扫描模式,配置如下:

引脚原理图如下:

5.DAC0配置如下:

P014引脚原理图如下:

6.Timer0 普通定时1s,控制LED D6闪烁,配置如下:

7.Timer2 PWM输出控制LED D3,配置如下

P103外引引脚原理图如下:

8.Timer5 输入捕获(PWM脉宽和周期测量,测试Timer2产生的PWM波),配置如下

P101外引引脚原理图如下:

如上,这次需要测试的功能模块的所有配置已经完成了,点击如下红框内的按钮就生成Keil工程代码

下面进行功能验证代码的介绍,

1.systick功能

提供系统时基,代码如下:

volatile uint64_t SysTickms = 0;

fsp_err_t SystickInit(void)

{

uint32_t uwSysclk = R_BSP_SourceClockHzGet(FSP_PRIV_CLOCK_PLL);

if (SysTick_Config(uwSysclk / 1000) != 0)

{

return FSP_ERR_ASSERTION;

}

return FSP_SUCCESS;

}

void SysTick_Handler(void)

{

SysTickms += 1;

}

在主函数中调用SystickInit()即可。

2.uart

主要用于输出调试信息,

这里移植了一个letter_shell和lwrb库,letter_shell实现了类似linux控制台命令行的交互效果,源码地址如下:

https://github.com/NevermindZZT/letter-shell

lwrb库用来处理接收到的串口数据,直接丢入ringbuf中,需要的时候取出来数据使用即可,源码地址如下:

https://github.com/MaJerle/lwrb

具体移植方法可以阅读源码里的README.md文档。

工程中代码如下

#include "lwrb/lwrb.h"

#include "shell_port.h"

lwrb_t buff = {0};

uint8_t buff_data[256];

err = g_uart9.p_api->open(g_uart9.p_ctrl, g_uart9.p_cfg);

assert(FSP_SUCCESS == err);

lwrb_init(&buff, buff_data, sizeof(buff_data));

userShellInit();

串口中断函数如下

static volatile bool g_uart9_tx_complete = false;

static volatile bool g_uart9_rx_complete = false;

void user_uart9_callback (uart_callback_args_t * p_args)

{

switch (p_args->event)

{

case UART_EVENT_TX_DATA_EMPTY:

{

break;

}

case UART_EVENT_TX_COMPLETE:

{

g_uart9_tx_complete = true;

break;

}

case UART_EVENT_RX_COMPLETE:

{

g_uart9_rx_complete = true;

break;

}

case UART_EVENT_RX_CHAR:

{

lwrb_write(&buff, (uint8_t*)&p_args->data, 1);

break;

}

default:

{

break;

}

}

}

void uart9_wait_for_tx(void)

{

while (!g_uart9_tx_complete);

g_uart9_tx_complete = false;

}

void uart9_wait_for_rx(void)

{

while (!g_uart9_rx_complete);

g_uart9_rx_complete = false;

}

letter_shell其他接口移植函数如下:

#include "shell.h"

#include "hal_data.h"

#include "log.h"

Shell shell;

char shellBuffer[256];

#if (HELL_TASK_WHILE == 1)

#include "FreeRTOS.h"

#include "task.h"

static SemaphoreHandle_t shellMutex;

#endif

short userShellWrite(char *data, unsigned short len)

{

g_uart9.p_api->write(g_uart9.p_ctrl, (uint8_t const *const)data, (uint32_t)len);

uart9_wait_for_tx();

return (short)len;

}

short userShellRead(char *data, unsigned short len)

{

(void)data;

(void)len;

return 0;

}

int userShellLock(Shell *sh)

{

(void)(sh);

#if (HELL_TASK_WHILE == 1)

xSemaphoreTakeRecursive(shellMutex, portMAX_DELAY);

#endif

return 0;

}

int userShellUnlock(Shell *sh)

{

(void)(sh);

#if (HELL_TASK_WHILE == 1)

xSemaphoreGiveRecursive(shellMutex);

#endif

return 0;

}

void uartLogWrite(char *buffer, short len);

Log uartLog = {

.write = uartLogWrite,

.active = 1,

.level = LOG_DEBUG

};

void uartLogWrite(char *buffer, short len)

{

if (uartLog.shell)

{

shellWriteEndLine(uartLog.shell, buffer, len);

}

}

void userShellInit(void)

{

#if (HELL_TASK_WHILE == 1)

shellMutex = xSemaphoreCreateMutex();

shell.lock = userShellLock;

shell.unlock = userShellUnlock;

#endif

shell.write = userShellWrite;

shellInit(&shell, shellBuffer, sizeof(shellBuffer));

logRegister(&uartLog, &shell);

#if (HELL_TASK_WHILE == 1)

if (xTaskCreate(shellTask, "shell", 256, &shell, 5, NULL) != pdPASS)

{

logError("shell task creat failed");

}

#endif

}

static const char *shellText[] =

{

#if SHELL_SHOW_INFO == 1

[SHELL_TEXT_INFO] =

"\\\\r\\\\n"

#if 0

" _ _ _ _ _ _ \\\\r\\\\n"

"| | ___| |_| |_ ___ _ __ ___| |__ ___| | |\\\\r\\\\n"

"| | / _ \\\\\\\\ __| __/ _ \\\\\\\\ '__| / __| '_ \\\\\\\\ / _ \\\\\\\\ | |\\\\r\\\\n"

"| |__| __/ |_| || __/ | \\\\\\\\__ \\\\\\\\ | | | __/ | |\\\\r\\\\n"

"|_____\\\\\\\\___|\\\\\\\\__|\\\\\\\\__\\\\\\\\___|_| |___/_| |_|\\\\\\\\___|_|_|\\\\r\\\\n"

#else

" ____ ___ __ __ __ ______ _____ \\\\r\\\\n"

" / __ \\\\\\\\/ | / // / / |/ /__ \\\\\\\\ / ___/___ ____ _________ _____\\\\r\\\\n"

" / /_/ / /| |/ // /_/ /|_/ /__/ / \\\\\\\\__ \\\\\\\\/ _ \\\\\\\\/ __ \\\\\\\\/ ___/ __ \\\\\\\\/ ___/\\\\r\\\\n"

" / _, _/ ___ /__ __/ / / // __/ ___/ / __/ / / (__ ) /_/ / / \\\\r\\\\n"

"/_/ |_/_/ |_| /_/ /_/ /_//____/____/____/\\\\\\\\___/_/ /_/____/\\\\\\\\____/_/ \\\\r\\\\n"

" /_____/ \\\\r\\\\n"

#endif

"\\\\r\\\\n"

"Build: "__DATE__" "__TIME__"\\\\r\\\\n"

"Version: "SHELL_VERSION"\\\\r\\\\n"

"Copyright: (c) 2020 Letter\\\\r\\\\n",

#endif

[SHELL_TEXT_CMD_TOO_LONG] =

"\\\\r\\\\nWarning: Command is too long\\\\r\\\\n",

[SHELL_TEXT_CMD_LIST] =

"\\\\r\\\\nCommand List:\\\\r\\\\n",

[SHELL_TEXT_VAR_LIST] =

"\\\\r\\\\nVar List:\\\\r\\\\n",

[SHELL_TEXT_USER_LIST] =

"\\\\r\\\\nUser List:\\\\r\\\\n",

[SHELL_TEXT_KEY_LIST] =

"\\\\r\\\\nKey List:\\\\r\\\\n",

[SHELL_TEXT_CMD_NOT_FOUND] =

"Command not Found\\\\r\\\\n",

[SHELL_TEXT_POINT_CANNOT_MODIFY] =

"can't set pointer\\\\r\\\\n",

[SHELL_TEXT_VAR_READ_ONLY_CANNOT_MODIFY] =

"can't set read only var\\\\r\\\\n",

[SHELL_TEXT_NOT_VAR] =

" is not a var\\\\r\\\\n",

[SHELL_TEXT_VAR_NOT_FOUND] =

"Var not Fount\\\\r\\\\n",

[SHELL_TEXT_HELP_HEADER] =

"command help of ",

[SHELL_TEXT_PASSWORD_HINT] =

"Please input password:",

[SHELL_TEXT_PASSWORD_ERROR] =

"\\\\r\\\\npassword error\\\\r\\\\n",

[SHELL_TEXT_CLEAR_CONSOLE] =

"\\\\033[2J\\\\033[1H",

[SHELL_TEXT_CLEAR_LINE] =

"\\\\033[2K\\\\r",

[SHELL_TEXT_TYPE_CMD] =

"CMD ",

[SHELL_TEXT_TYPE_VAR] =

"VAR ",

[SHELL_TEXT_TYPE_USER] =

"USER",

[SHELL_TEXT_TYPE_KEY] =

"KEY ",

[SHELL_TEXT_TYPE_NONE] =

"NONE",

#if SHELL_EXEC_UNDEF_FUNC == 1

[SHELL_TEXT_PARAM_ERROR] =

"Parameter error\\\\r\\\\n",

#endif

};

在while循环中调用如下函数就完成了letter_shell的功能,同时也完成了自带的log输出功能。

if (lwrb_get_full(&buff))

{

char ch = '0';

lwrb_read(&buff,&ch,1);

shellHandler(&shell, ch);

}

效果如下:

3.按键

移植了MultiButton库,实现按键的单击、双击、长按的处理,MultiButton源码地址如下:

https://github.com/0x1abin/MultiButton

具体移植方法可以阅读源码里的README.md文档。工程中代码如下

#include "multi_button.h"

enum Button_IDs {

btn1_id = 0,

btn2_id,

btn3_id,

btn_max,

};

struct Button btn[btn_max];

uint8_t read_button_GPIO(uint8_t button_id)

{

bsp_io_level_t btnState = BSP_IO_LEVEL_HIGH;

switch(button_id)

{

case btn1_id:

R_IOPORT_PinRead(&g_ioport_ctrl, BSP_IO_PORT_00_PIN_13, &btnState);

break;

case btn2_id:

R_IOPORT_PinRead(&g_ioport_ctrl, BSP_IO_PORT_01_PIN_12, &btnState);

break;

case btn3_id:

R_IOPORT_PinRead(&g_ioport_ctrl, BSP_IO_PORT_01_PIN_11, &btnState);

break;

default:

break;

}

return (uint8_t)btnState;

}

void Callback_btn_Handler(void *btn_ptr)

{

Button *_btn = (Button *)btn_ptr;

switch (_btn->event)

{

case PRESS_DOWN:

logInfo("BTN[%d] press down!",_btn->button_id+1);

break;

case PRESS_UP:

logInfo("BTN[%d] press up!",_btn->button_id+1);

break;

case PRESS_REPEAT:

logInfo("BTN[%d] press repeat!",_btn->button_id+1);

break;

case SINGLE_CLICK:

logInfo("BTN[%d] single click!",_btn->button_id+1);

break;

case DOUBLE_CLICK:

logInfo("BTN[%d] double click!",_btn->button_id+1);

break;

case LONG_PRESS_START:

logInfo("BTN[%d] long press start!",_btn->button_id+1);

break;

case LONG_PRESS_HOLD:

logInfo("BTN[%d] long press hold!",_btn->button_id+1);

break;

default:

break;

}

}

for (uint8_t i = 0; i < btn_max; i++) {

button_init(&btn[i], read_button_GPIO, 0, i);

button_attach(&btn[i], PRESS_DOWN, Callback_btn_Handler);

button_attach(&btn[i], PRESS_UP, Callback_btn_Handler);

button_attach(&btn[i], PRESS_REPEAT, Callback_btn_Handler);

button_attach(&btn[i], SINGLE_CLICK, Callback_btn_Handler);

button_attach(&btn[i], DOUBLE_CLICK, Callback_btn_Handler);

button_attach(&btn[i], LONG_PRESS_START, Callback_btn_Handler);

button_attach(&btn[i], LONG_PRESS_HOLD, Callback_btn_Handler);

button_start(&btn[i]);

}

// 按键任务处理函数,需要在while循环中5ms周期调用

if (btn_tick < SysTickms)

{

button_ticks();

btn_tick = SysTickms + 5;

}

到此就完成了按键的功能测试,按下按键后终端控制台会打印相应的信息,效果如下:

3.ADC和TSN

uint16_t adc_val[8];

float temperature = 0.0f;

int gi_temperature = 0;

SHELL_EXPORT_VAR(SHELL_CMD_PERMISSION(0)|SHELL_CMD_TYPE(SHELL_TYPE_VAR_INT), gettemperature, &gi_temperature, test); // 用于通过shell获取温度,放大100倍显示

logDebug("Start Open adc0");

err = g_adc0.p_api->open(g_adc0.p_ctrl,g_adc0.p_cfg);

assert(FSP_SUCCESS == err);

err = g_adc0.p_api->scanCfg(g_adc0.p_ctrl,g_adc0.p_channel_cfg);

assert(FSP_SUCCESS == err);

logDebug("Open adc0 end");

logDebug("Start adc0 scan");

g_adc0.p_api->scanStart(g_adc0.p_ctrl);

如上代码在入口函数中执行一次即可。

adc中断函数如下:

volatile bool scan_complete_flag = false;

void user_adc_callback(adc_callback_args_t * p_args)

{

FSP_PARAMETER_NOT_USED(p_args);

scan_complete_flag = true;

}

void adc_wait_for_scan(void)

{

while (!scan_complete_flag);

scan_complete_flag = false;

}

bool get_adc_scan_status(void)

{

return scan_complete_flag;

}

void reset_adc_scan_state(void)

{

scan_complete_flag = false;

}

4.ADC数据读取及TSN计算代码如下,

if (get_adc_scan_status())

{

g_adc0.p_api->read(g_adc0.p_ctrl,ADC_CHANNEL_0,&adc_val[0]);

g_adc0.p_api->read(g_adc0.p_ctrl,ADC_CHANNEL_TEMPERATURE,&adc_val[1]);

int32_t cal127;

adc_info_t adc_info;

(void) R_ADC_InfoGet(&g_adc0_ctrl, &adc_info);

cal127 = (int32_t) adc_info.calibration_data;

float slope = 4.0f/1000.0f;

float v1= 3.3f * (float)cal127 / 4096.0f;

float vs = 3.3f * (float)adc_val[1] /4096.0f;

temperature = (vs - v1) / slope + 127.0f;

gi_temperature = (int)(temperature * 100.0f);

reset_adc_scan_state();

}

ADC的通道上外接了了一个光敏电阻传感器模块,可以通过读取其数值来控制led D2的亮灭,代码如下:

if (led1_tick < SysTickms)

{

led1_tick = SysTickms + 100;

g_ioport.p_api->pinWrite(g_ioport.p_ctrl, BSP_IO_PORT_00_PIN_02, (adc_val[0]>2000));

}

如上代码需要在while循环中周期执行,至此,ADC和TSN的代码介绍完毕,效果如下

通过shell获取温度

光敏电阻控制led,接近光影D2熄灭,拿开D2点亮。

5.DAC0,输出正弦波代码如下:

//正弦波数据数组变量,根据计算得来

const uint16_t sindata[] = {

2048, 2460, 2856, 3218, 3532, 3786, 3969, 4072, 4093, 4031, 3887, 3668,

3382, 3042, 2661, 2255, 1841, 1435, 1054, 714, 428, 209, 65, 3, 24, 127,

310, 564, 878, 1240, 1636, 2048

};

logDebug("Start Open and start dac0");

err = g_dac0.p_api->open(g_dac0.p_ctrl,g_dac0.p_cfg);

assert(FSP_SUCCESS == err);

err = g_dac0.p_api->start(g_dac0.p_ctrl);

assert(FSP_SUCCESS == err);

logDebug("Open dac0 end");

// 1ms dac-->sin while循环中周期调用

if (_ms != SysTickms)

{

if (sindataindex >= 32) {

sindataindex = 0;

}

g_dac0.p_api->write(g_dac0.p_ctrl,sindata[sindataindex++]);

// DAC_SetVoltage(vol);

}

通过示波器测量P014引脚,效果如头部视频所示。

6.Timer0,1s周期控制led D6闪烁,代码如下:

logDebug("Start Open and start timer0");

err = g_timer0.p_api->open(g_timer0.p_ctrl,g_timer0.p_cfg);

assert(FSP_SUCCESS == err);

err = g_timer0.p_api->start(g_timer0.p_ctrl);

assert(FSP_SUCCESS == err);

logDebug("Open timer0 end");

void user_timer0_callback(timer_callback_args_t * p_args)

{

static bsp_io_level_t level_led3 = BSP_IO_LEVEL_HIGH;

if (TIMER_EVENT_CYCLE_END == p_args->event)

{

g_ioport.p_api->pinWrite(g_ioport.p_ctrl, BSP_IO_PORT_01_PIN_04, level_led3);

level_led3 = !level_led3;

}

}

将光敏电阻靠近光源来控制D2熄灭,突出D6的闪烁效果,如下:

7.Timer2 输出PWM波形,代码如下:

uint8_t gpt2_pwma_duty = 20

SHELL_EXPORT_VAR(SHELL_CMD_PERMISSION(0)|SHELL_CMD_TYPE(SHELL_TYPE_VAR_CHAR), varPwm, &gpt2_pwma_duty, test)

void GPT2_PWMA_SetDuty(uint8_t duty)

{

timer_info_t info;

uint32_t current_period_counts;

uint32_t duty_cycle_counts;

if (duty > 100)

duty = 100;

g_timer0.p_api->infoGet(g_timer2.p_ctrl, &info);

current_period_counts = info.period_counts;

duty_cycle_counts = (uint32_t)(((uint64_t) current_period_counts * duty) / 100);

g_timer0.p_api->dutyCycleSet(g_timer2.p_ctrl, duty_cycle_counts, GPT_IO_PIN_GTIOCA);

}

logDebug("Start Open and start timer2 pwm");

err = g_timer2.p_api->open(g_timer2.p_ctrl,g_timer2.p_cfg);

assert(FSP_SUCCESS == err);

err = g_timer2.p_api->start(g_timer2.p_ctrl);

assert(FSP_SUCCESS == err);

GPT2_PWMA_SetDuty(gpt2_pwma_duty);

logDebug("Open timer2 pwm end");

// while循环里周期调用,修改gpt2_pwma_duty的数值即可改变占空比,默认20%

GPT2_PWMA_SetDuty(gpt2_pwma_duty);

通过逻辑分析仪测量P103或者观察LED D3的光亮强度可以反馈占空比的大小。

30%

50%

80%

通过修改占空比,肉眼可见LED D3光亮强度会改变

8.Timer5 输入捕获,测量PWM周期、频率、占空比,代码如下:

timer_info_t info;

uint32_t period;

uint32_t pwm_period;

uint32_t pwm_high_level_time;

uint32_t pwm_freq;

uint32_t pwm_duty;

logDebug("Start Open and start timer5 cap");

err = g_timer5.p_api->open(g_timer5.p_ctrl,g_timer5.p_cfg);

assert(FSP_SUCCESS == err);

err = g_timer5.p_api->infoGet(g_timer5.p_ctrl,&info);

assert(FSP_SUCCESS == err);

period = info.period_counts;

err = g_timer5.p_api->enable(g_timer5.p_ctrl);

assert(FSP_SUCCESS == err);

err = g_timer5.p_api->start(g_timer5.p_ctrl);

assert(FSP_SUCCESS == err);

logDebug("Open timer5 cap end");

// while循环中1s周期执行,打印结果

if (_sec < SysTickms)

{

_sec = SysTickms + 1000;

/* 计算PWM的频率 */

pwm_freq = info.clock_frequency / pwm_period;

/* 计算PWM的占空比 */

pwm_duty = pwm_high_level_time * 100 / pwm_period;

// 打印

logInfo("High=%d, Period=%d, ", pwm_high_level_time, pwm_period);

logInfo("Friquency = %dHz, Duty_Cycle = %d%%", pwm_freq, pwm_duty);

pwm_period = pwm_high_level_time = pwm_freq = 0; //打印完后旧数据清零

}

void user_timer5_callback(timer_callback_args_t * p_args)

{

static uint32_t a_time;

static uint32_t b_time;

static uint32_t c_time;

static uint32_t overflow_times;

static uint8_t one_period_flag=0;

switch(p_args->event)

{

case TIMER_EVENT_CAPTURE_A:

if (0 == one_period_flag)

{

a_time = p_args->capture;

overflow_times = 0;

one_period_flag ++;

}

else if (1 == one_period_flag)

{

c_time = p_args->capture + overflow_times * period;

pwm_period = c_time - a_time;

overflow_times = 0;

one_period_flag = 0;

}

break;

case TIMER_EVENT_CAPTURE_B:

if (1 == one_period_flag)

{

b_time = p_args->capture + overflow_times * period;

pwm_high_level_time = b_time - a_time;

}

break;

case TIMER_EVENT_CYCLE_END:

overflow_times++;

break;

default:

break;

}

}

直接测量Timer2 P103引脚的信号,将P103和P101连接在一起,效果如下:

默认20%,20KHz.

视频效果见底部视频

keil整体工程:*附件:RA4M2_Sensor.7z

/9

/9