适配 ST7789v LCD

R128 平台提供了 SPI DBI 的 SPI TFT 接口,具有如下特点:

- Supports DBI Type C 3 Line/4 Line Interface Mode

- Supports 2 Data Lane Interface Mode

- Supports data source from CPU or DMA

- Supports RGB111/444/565/666/888 video format

- Maximum resolution of RGB666 240 x 320@30Hz with single data lane

- Maximum resolution of RGB888 240 x 320@60Hz or 320 x 480@30Hz with dual data lane

- Supports tearing effect

- Supports software flexible control video frame rate

同时,提供了 SPILCD 驱动框架以供 SPI 屏幕使用。

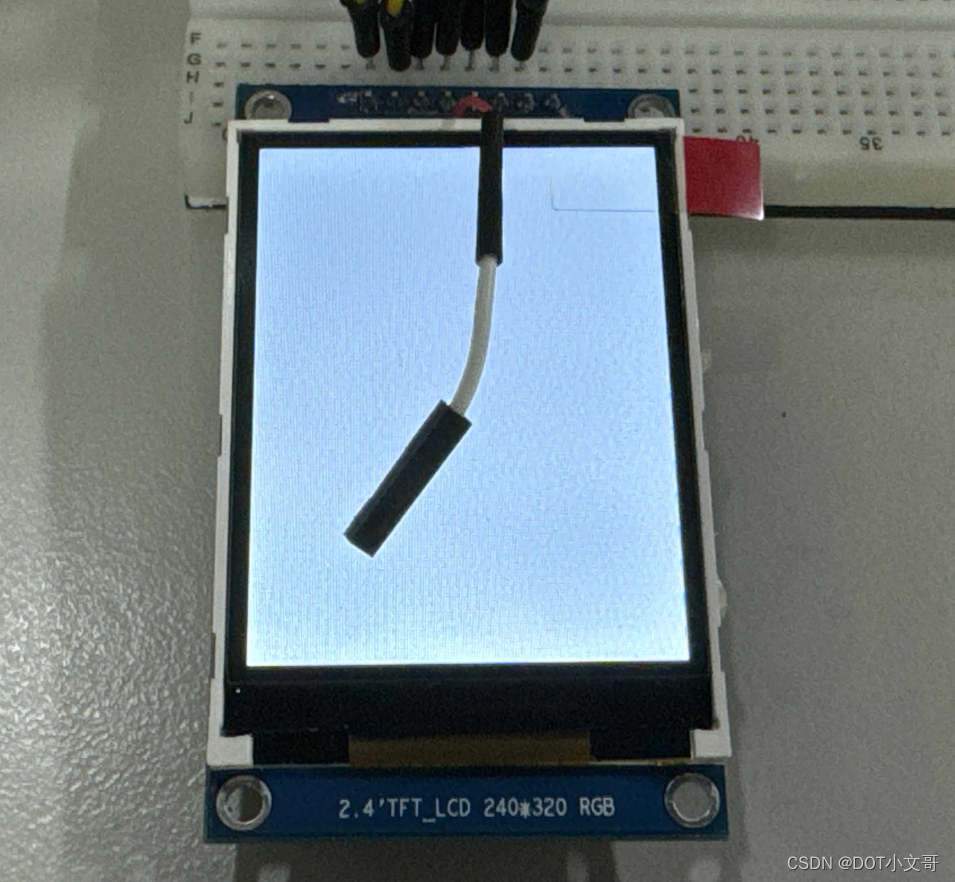

此次适配的SPI屏为 ZJY240S0800TG11,使用的是 SPI 进行驱动。注意请购买带 CS 引脚的 SPI 屏幕,由于 ST7789v SPI 时序问题,CS 引脚直接接地可能会导致初始化无法写入。如果很不幸SPI TFT是不带 CS 的,请飞线出来连接 CS 引脚(如图所示)

引脚配置如下:

| R128 Devkit |

TFT 模块 |

|---|

| PA12 |

CS(飞线) |

| PA13 |

CLK |

| PA18 |

MOSI |

| PA9 |

BLK |

| PA20 |

RES |

| PA19 |

DC |

| 3V3 |

VCC |

| GND |

GND |

| 悬空 |

MISO |

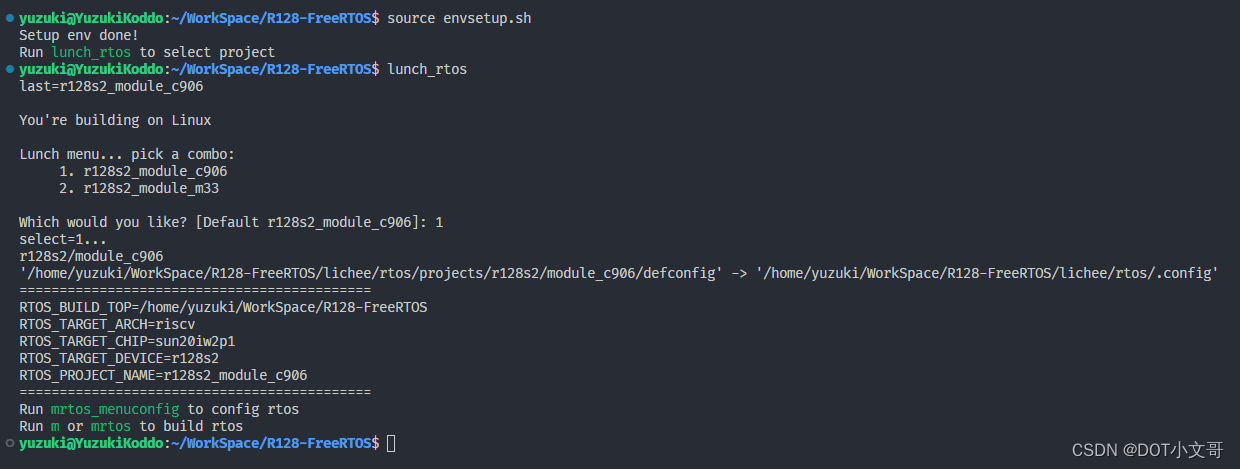

载入方案

我们使用的开发板是 R128-Devkit,需要开发 C906 核心的应用程序,所以载入方案选择 r128s2_module_c906

$ source envsetup.sh

$ lunch_rtos 1

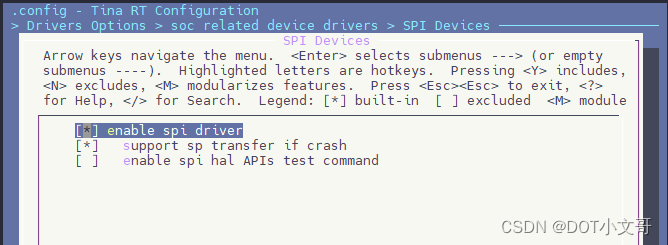

设置 SPI 驱动

屏幕使用的是SPI驱动,所以需要勾选SPI驱动,运行 mrtos_menuconfig 进入配置页面。前往下列地址找到 SPI Devices

Drivers Options --->

soc related device drivers --->

SPI Devices --->

-*- enable spi driver

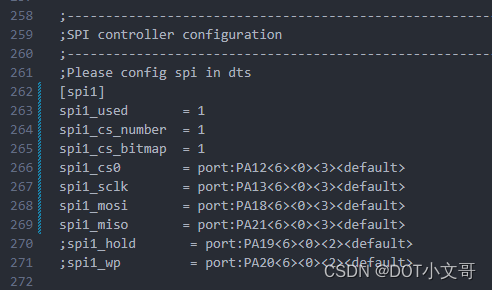

配置 SPI 引脚

打开你喜欢的编辑器,修改文件:board/r128s2/module/configs/sys_config.fex,在这里我们不需要用到 SPI HOLD与SPI WP引脚,注释掉即可。

;----------------------------------------------------------------------------------

;SPI controller configuration

;----------------------------------------------------------------------------------

;Please config spi in dts

[spi1]

spi1_used = 1

spi1_cs_number = 1

spi1_cs_bitmap = 1

spi1_cs0 = port:PA12<6><0><3><default>

spi1_sclk = port:PA13<6><0><3><default>

spi1_mosi = port:PA18<6><0><3><default>

spi1_miso = port:PA21<6><0><3><default>

;spi1_hold = port:PA19<6><0><2><default>

;spi1_wp = port:PA20<6><0><2><default>

设置 PWM 驱动

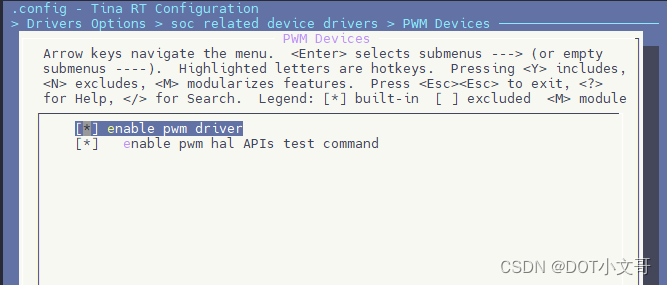

屏幕背光使用的是PWM驱动,所以需要勾选PWM驱动,运行 mrtos_menuconfig 进入配置页面。前往下列地址找到 PWM Devices

Drivers Options

soc related device drivers

PWM Devices

-*- enable pwm driver

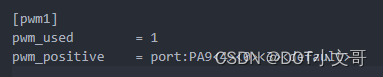

配置 PWM 引脚

打开你喜欢的编辑器,修改文件:board/r128s2/module/configs/sys_config.fex,增加 PWM1 节点

[pwm1]

pwm_used = 1

pwm_positive = port:PA9<4><0><3><default>

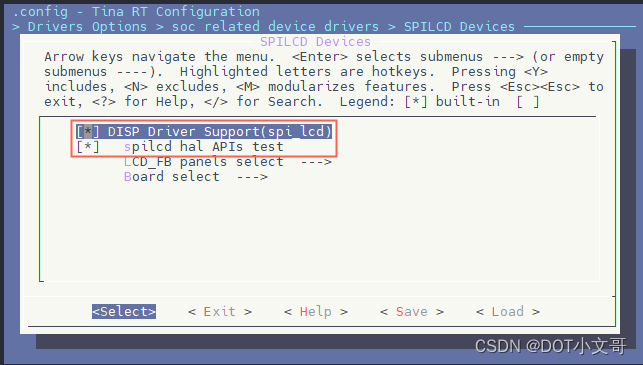

设置 SPI LCD 驱动

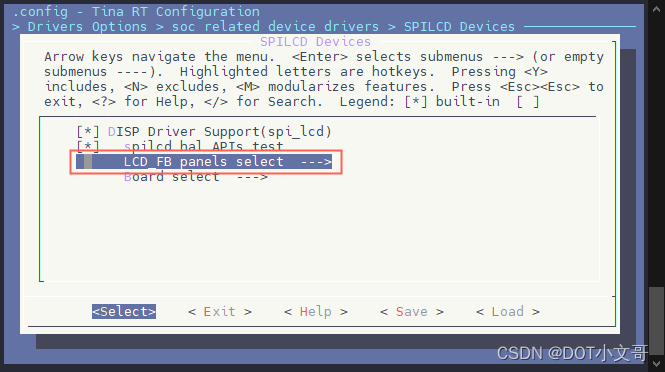

SPI LCD 由专门的驱动管理。运行 mrtos_menuconfig 进入配置页面。前往下列地址找到 SPILCD Devices ,注意同时勾选 spilcd hal APIs test 方便测试使用。

Drivers Options --->

soc related device drivers --->

[*] DISP Driver Support(spi_lcd)

[*] spilcd hal APIs test

编写 SPI LCD 显示屏驱动

获取屏幕初始化序列

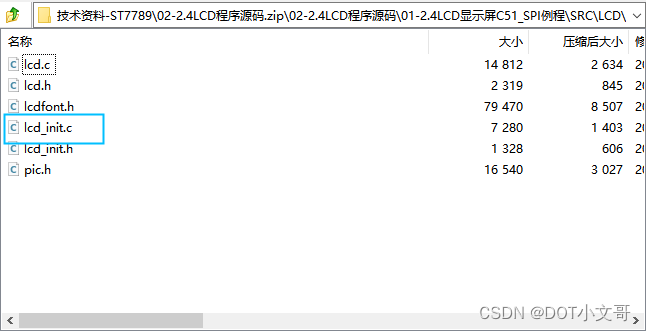

首先询问屏厂提供驱动源码

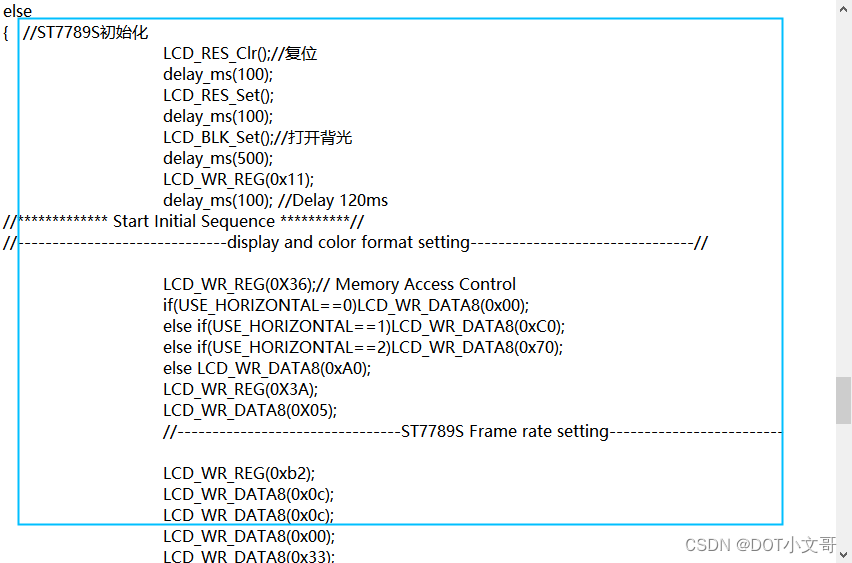

找到 LCD 的初始化序列代码

找到屏幕初始化的源码

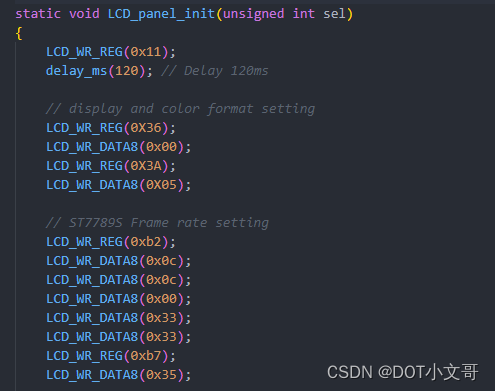

整理后的初始化代码如下:

LCD_WR_REG(0x11);

delay_ms(120);

LCD_WR_REG(0X36);

LCD_WR_DATA8(0x00);

LCD_WR_REG(0X3A);

LCD_WR_DATA8(0X05);

LCD_WR_REG(0xb2);

LCD_WR_DATA8(0x0c);

LCD_WR_DATA8(0x0c);

LCD_WR_DATA8(0x00);

LCD_WR_DATA8(0x33);

LCD_WR_DATA8(0x33);

LCD_WR_REG(0xb7);

LCD_WR_DATA8(0x35);

LCD_WR_REG(0xbb);

LCD_WR_DATA8(0x35);

LCD_WR_REG(0xc0);

LCD_WR_DATA8(0x2c);

LCD_WR_REG(0xc2);

LCD_WR_DATA8(0x01);

LCD_WR_REG(0xc3);

LCD_WR_DATA8(0x13);

LCD_WR_REG(0xc4);

LCD_WR_DATA8(0x20);

LCD_WR_REG(0xc6);

LCD_WR_DATA8(0x0f);

LCD_WR_REG(0xca);

LCD_WR_DATA8(0x0f);

LCD_WR_REG(0xc8);

LCD_WR_DATA8(0x08);

LCD_WR_REG(0x55);

LCD_WR_DATA8(0x90);

LCD_WR_REG(0xd0);

LCD_WR_DATA8(0xa4);

LCD_WR_DATA8(0xa1);

LCD_WR_REG(0xe0);

LCD_WR_DATA8(0xd0);

LCD_WR_DATA8(0x00);

LCD_WR_DATA8(0x06);

LCD_WR_DATA8(0x09);

LCD_WR_DATA8(0x0b);

LCD_WR_DATA8(0x2a);

LCD_WR_DATA8(0x3c);

LCD_WR_DATA8(0x55);

LCD_WR_DATA8(0x4b);

LCD_WR_DATA8(0x08);

LCD_WR_DATA8(0x16);

LCD_WR_DATA8(0x14);

LCD_WR_DATA8(0x19);

LCD_WR_DATA8(0x20);

LCD_WR_REG(0xe1);

LCD_WR_DATA8(0xd0);

LCD_WR_DATA8(0x00);

LCD_WR_DATA8(0x06);

LCD_WR_DATA8(0x09);

LCD_WR_DATA8(0x0b);

LCD_WR_DATA8(0x29);

LCD_WR_DATA8(0x36);

LCD_WR_DATA8(0x54);

LCD_WR_DATA8(0x4b);

LCD_WR_DATA8(0x0d);

LCD_WR_DATA8(0x16);

LCD_WR_DATA8(0x14);

LCD_WR_DATA8(0x21);

LCD_WR_DATA8(0x20);

LCD_WR_REG(0x29);

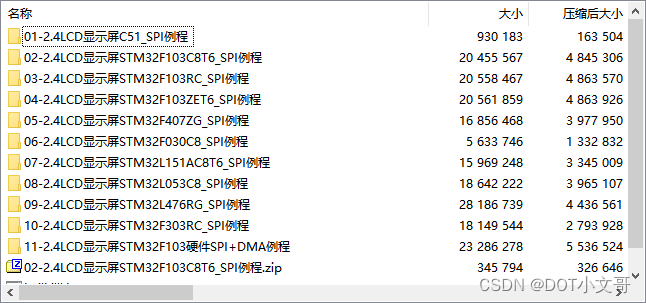

用现成驱动改写 SPI LCD 驱动

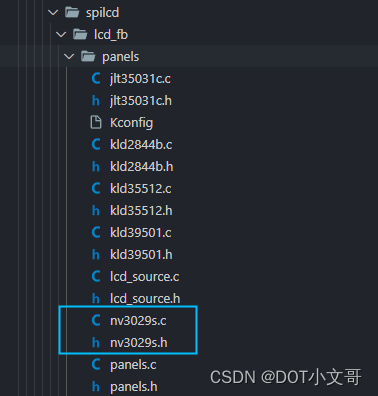

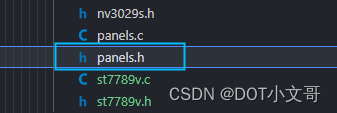

选择一个现成的 SPI LCD 改写即可,这里选择 nv3029s.c 驱动来修改

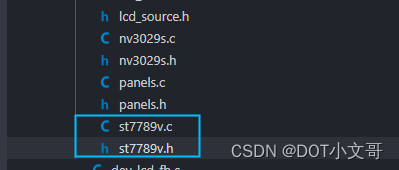

复制这两个驱动,重命名为 st7789v.c

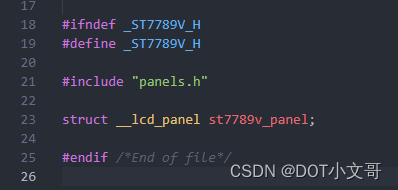

先编辑 st7789v.h 将 nv3029s 改成 st7789v

#ifndef _ST7789V_H

#define _ST7789V_H

#include "panels.h"

struct __lcd_panel st7789v_panel;

#endif

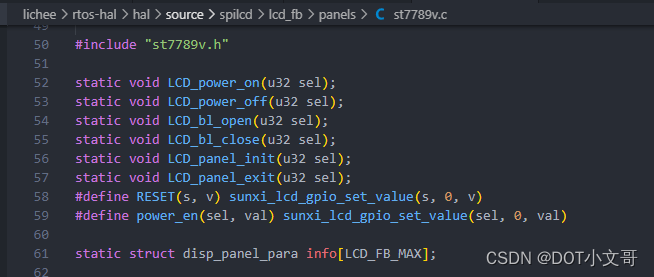

编辑 st7789v.c 将 nv3029s 改成 st7789v

然后将屏厂提供的初始化序列复制进来

然后按照 spi_lcd 框架的接口改写驱动接口,具体接口如下

| 屏厂函数 |

SPILCD框架接口 |

|---|

LCD_WR_REG |

sunxi_lcd_cmd_write |

LCD_WR_DATA8 |

sunxi_lcd_para_write |

delay_ms |

sunxi_lcd_delay_ms |

完成驱动如下

#include "st7789v.h"

static void LCD_power_on(u32 sel);

static void LCD_power_off(u32 sel);

static void LCD_bl_open(u32 sel);

static void LCD_bl_close(u32 sel);

static void LCD_panel_init(u32 sel);

static void LCD_panel_exit(u32 sel);

#define RESET(s, v) sunxi_lcd_gpio_set_value(s, 0, v)

#define power_en(sel, val) sunxi_lcd_gpio_set_value(sel, 0, val)

static struct disp_panel_para info[LCD_FB_MAX];

static void address(unsigned int sel, int x, int y, int width, int height)

{

sunxi_lcd_cmd_write(sel, 0x2B);

sunxi_lcd_para_write(sel, (y >> 8) & 0xff);

sunxi_lcd_para_write(sel, y & 0xff);

sunxi_lcd_para_write(sel, (height >> 8) & 0xff);

sunxi_lcd_para_write(sel, height & 0xff);

sunxi_lcd_cmd_write(sel, 0x2A);

sunxi_lcd_para_write(sel, (x >> 8) & 0xff);

sunxi_lcd_para_write(sel, x & 0xff);

sunxi_lcd_para_write(sel, (width >> 8) & 0xff);

sunxi_lcd_para_write(sel, width & 0xff);

sunxi_lcd_cmd_write(sel, 0x2c);

}

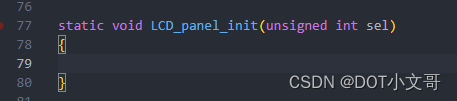

static void LCD_panel_init(unsigned int sel)

{

if (bsp_disp_get_panel_info(sel, &info[sel])) {

lcd_fb_wrn("get panel info fail!\n");

return;

}

sunxi_lcd_cmd_write(sel, 0x11);

sunxi_lcd_delay_ms(120);

sunxi_lcd_cmd_write(sel, 0X36);

sunxi_lcd_para_write(sel, 0x00);

sunxi_lcd_cmd_write(sel, 0X3A);

sunxi_lcd_para_write(sel, 0X05);

sunxi_lcd_cmd_write(sel, 0xb2);

sunxi_lcd_para_write(sel, 0x0c);

sunxi_lcd_para_write(sel, 0x0c);

sunxi_lcd_para_write(sel, 0x00);

sunxi_lcd_para_write(sel, 0x33);

sunxi_lcd_para_write(sel, 0x33);

sunxi_lcd_cmd_write(sel, 0xb7);

sunxi_lcd_para_write(sel, 0x35);

sunxi_lcd_cmd_write(sel, 0xbb);

sunxi_lcd_para_write(sel, 0x35);

sunxi_lcd_cmd_write(sel, 0xc0);

sunxi_lcd_para_write(sel, 0x2c);

sunxi_lcd_cmd_write(sel, 0xc2);

sunxi_lcd_para_write(sel, 0x01);

sunxi_lcd_cmd_write(sel, 0xc3);

sunxi_lcd_para_write(sel, 0x13);

sunxi_lcd_cmd_write(sel, 0xc4);

sunxi_lcd_para_write(sel, 0x20);

sunxi_lcd_cmd_write(sel, 0xc6);

sunxi_lcd_para_write(sel, 0x0f);

sunxi_lcd_cmd_write(sel, 0xca);

sunxi_lcd_para_write(sel, 0x0f);

sunxi_lcd_cmd_write(sel, 0xc8);

sunxi_lcd_para_write(sel, 0x08);

sunxi_lcd_cmd_write(sel, 0x55);

sunxi_lcd_para_write(sel, 0x90);

sunxi_lcd_cmd_write(sel, 0xd0);

sunxi_lcd_para_write(sel, 0xa4);

sunxi_lcd_para_write(sel, 0xa1);

sunxi_lcd_cmd_write(sel, 0xe0);

sunxi_lcd_para_write(sel, 0xd0);

sunxi_lcd_para_write(sel, 0x00);

sunxi_lcd_para_write(sel, 0x06);

sunxi_lcd_para_write(sel, 0x09);

sunxi_lcd_para_write(sel, 0x0b);

sunxi_lcd_para_write(sel, 0x2a);

sunxi_lcd_para_write(sel, 0x3c);

sunxi_lcd_para_write(sel, 0x55);

sunxi_lcd_para_write(sel, 0x4b);

sunxi_lcd_para_write(sel, 0x08);

sunxi_lcd_para_write(sel, 0x16);

sunxi_lcd_para_write(sel, 0x14);

sunxi_lcd_para_write(sel, 0x19);

sunxi_lcd_para_write(sel, 0x20);

sunxi_lcd_cmd_write(sel, 0xe1);

sunxi_lcd_para_write(sel, 0xd0);

sunxi_lcd_para_write(sel, 0x00);

sunxi_lcd_para_write(sel, 0x06);

sunxi_lcd_para_write(sel, 0x09);

sunxi_lcd_para_write(sel, 0x0b);

sunxi_lcd_para_write(sel, 0x29);

sunxi_lcd_para_write(sel, 0x36);

sunxi_lcd_para_write(sel, 0x54);

sunxi_lcd_para_write(sel, 0x4b);

sunxi_lcd_para_write(sel, 0x0d);

sunxi_lcd_para_write(sel, 0x16);

sunxi_lcd_para_write(sel, 0x14);

sunxi_lcd_para_write(sel, 0x21);

sunxi_lcd_para_write(sel, 0x20);

sunxi_lcd_cmd_write(sel, 0x29);

if (info[sel].lcd_x < info[sel].lcd_y)

address(sel, 0, 0, info[sel].lcd_x - 1, info[sel].lcd_y - 1);

else

address(sel, 0, 0, info[sel].lcd_y - 1, info[sel].lcd_x - 1);

}

static void LCD_panel_exit(unsigned int sel)

{

sunxi_lcd_cmd_write(sel, 0x28);

sunxi_lcd_delay_ms(20);

sunxi_lcd_cmd_write(sel, 0x10);

sunxi_lcd_delay_ms(20);

sunxi_lcd_pin_cfg(sel, 0);

}

static s32 LCD_open_flow(u32 sel)

{

lcd_fb_here;

LCD_OPEN_FUNC(sel, LCD_power_on, 50);

LCD_OPEN_FUNC(sel, LCD_panel_init, 200);

LCD_OPEN_FUNC(sel, lcd_fb_black_screen, 50);

LCD_OPEN_FUNC(sel, LCD_bl_open, 0);

return 0;

}

static s32 LCD_close_flow(u32 sel)

{

lcd_fb_here;

LCD_CLOSE_FUNC(sel, LCD_bl_close, 50);

LCD_CLOSE_FUNC(sel, LCD_panel_exit, 10);

LCD_CLOSE_FUNC(sel, LCD_power_off, 10);

return 0;

}

static void LCD_power_on(u32 sel)

{

lcd_fb_here;

power_en(sel, 1);

sunxi_lcd_power_enable(sel, 0);

sunxi_lcd_pin_cfg(sel, 1);

RESET(sel, 1);

sunxi_lcd_delay_ms(100);

RESET(sel, 0);

sunxi_lcd_delay_ms(100);

RESET(sel, 1);

}

static void LCD_power_off(u32 sel)

{

lcd_fb_here;

sunxi_lcd_power_disable(sel, 0);

power_en(sel, 0);

}

static void LCD_bl_open(u32 sel)

{

sunxi_lcd_pwm_enable(sel);

sunxi_lcd_backlight_enable(sel);

lcd_fb_here;

}

static void LCD_bl_close(u32 sel)

{

sunxi_lcd_backlight_disable(sel);

sunxi_lcd_pwm_disable(sel);

lcd_fb_here;

}

static s32 LCD_user_defined_func(u32 sel, u32 para1, u32 para2, u32 para3)

{

lcd_fb_here;

return 0;

}

static int lcd_set_var(unsigned int sel, struct fb_info *p_info)

{

return 0;

}

static int lcd_set_addr_win(unsigned int sel, int x, int y, int width, int height)

{

address(sel, x, y, width, height);

return 0;

}

static int lcd_blank(unsigned int sel, unsigned int en)

{

return 0;

}

struct __lcd_panel st7789v_panel = {

.name = "st7789v",

.func = {

.cfg_open_flow = LCD_open_flow,

.cfg_close_flow = LCD_close_flow,

.lcd_user_defined_func = LCD_user_defined_func,

.blank = lcd_blank,

.set_var = lcd_set_var,

.set_addr_win = lcd_set_addr_win,

},

};

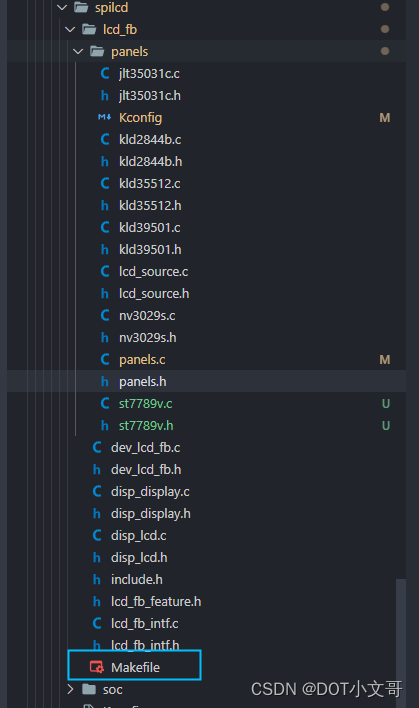

对接驱动框架

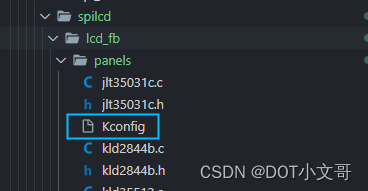

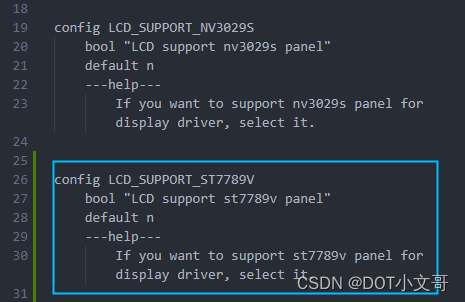

完成了屏幕驱动的编写,接下来需要对接到 SPILCD 驱动框架。首先编辑 Kconfig

增加 st7789v 的配置

config LCD_SUPPORT_ST7789V

bool "LCD support st7789v panel"

default n

If you want to support st7789v panel for display driver, select it.

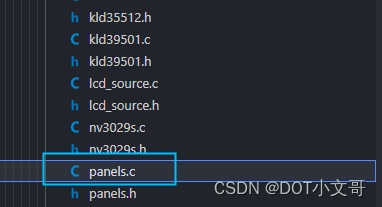

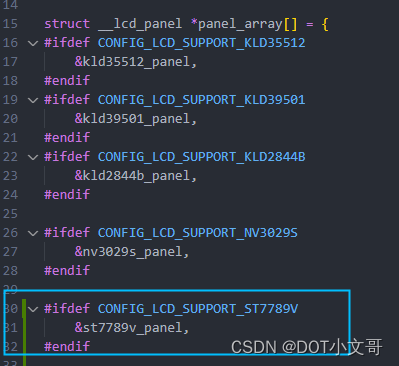

然后编辑 panels.c 在 panel_array 里增加 st7789 驱动的引用

如下图

#ifdef CONFIG_LCD_SUPPORT_ST7789V

&st7789v_panel,

#endif

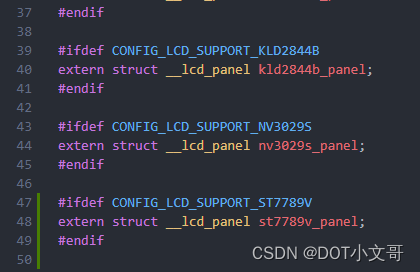

之后编辑 panels.h 同样增加引用

如下图

#ifdef CONFIG_LCD_SUPPORT_ST7789V

extern struct __lcd_panel st7789v_panel;

#endif

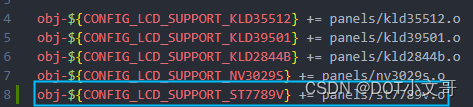

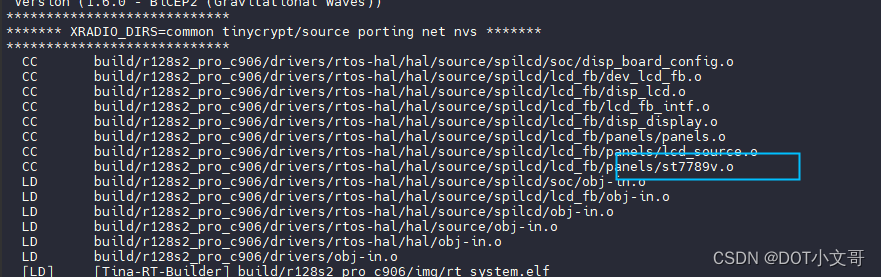

最后编辑外层的 Makefile 增加编译选项

如下所示

obj-${CONFIG_LCD_SUPPORT_ST7789V} += panels/st7789v.o

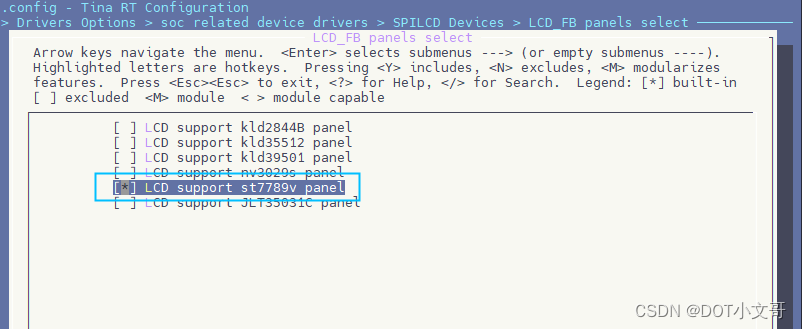

选择 ST7789V 驱动

在 SPILCD 驱动选择界面可以看到 LCD_FB panels select 选择 SPI 屏幕的驱动

进入 LCD_FB panels select 选项

选择并勾选 [*] LCD support st7789v panel

配置 SPI LCD 引脚

打开你喜欢的编辑器,修改文件:board/r128s2/module/configs/sys_config.fex

[lcd_fb0]

lcd_used = 1

lcd_model_name = "spilcd"

lcd_driver_name = "st7789v"

lcd_x = 240

lcd_y = 320

lcd_width = 37

lcd_height = 48

lcd_data_speed = 50

lcd_pwm_used = 1

lcd_pwm_ch = 1

lcd_pwm_freq = 5000

lcd_pwm_pol = 0

lcd_if = 0

lcd_pixel_fmt = 11

lcd_dbi_fmt = 2

lcd_dbi_clk_mode = 1

lcd_dbi_te = 1

fb_buffer_num = 2

lcd_dbi_if = 4

lcd_rgb_order = 0

lcd_fps = 60

lcd_spi_bus_num = 1

lcd_frm = 2

lcd_gamma_en = 1

lcd_backlight = 100

lcd_power_num = 0

lcd_gpio_regu_num = 0

lcd_bl_percent_num = 0

lcd_spi_dc_pin = port:PA19<1><0><3><0>

lcd_gpio_0 = port:PA20<1><0><2><0>

编译打包

运行命令 mp 编译打包,可以看到编译了 st7789v.o

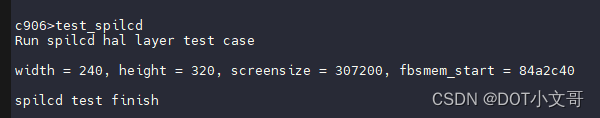

测试

烧录启动之后,屏幕背光启动,但是屏幕全黑。

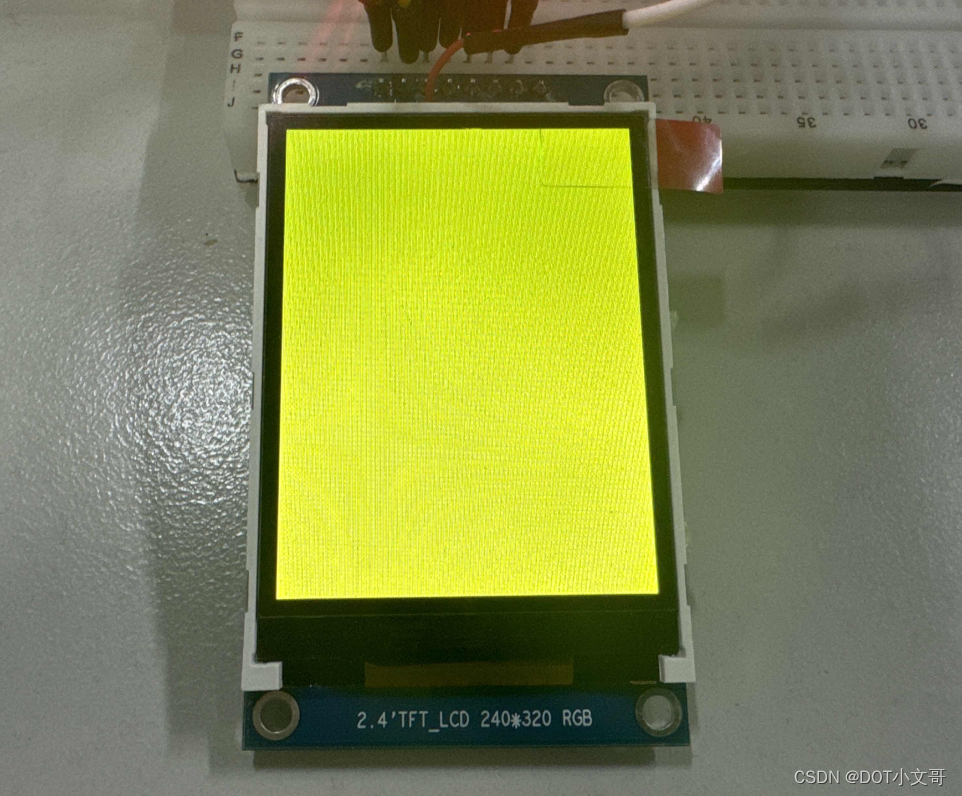

输入 test_spilcd ,屏幕显示黄色。

输入 lv_examples 1 可以显示 lvgl 界面

常见问题

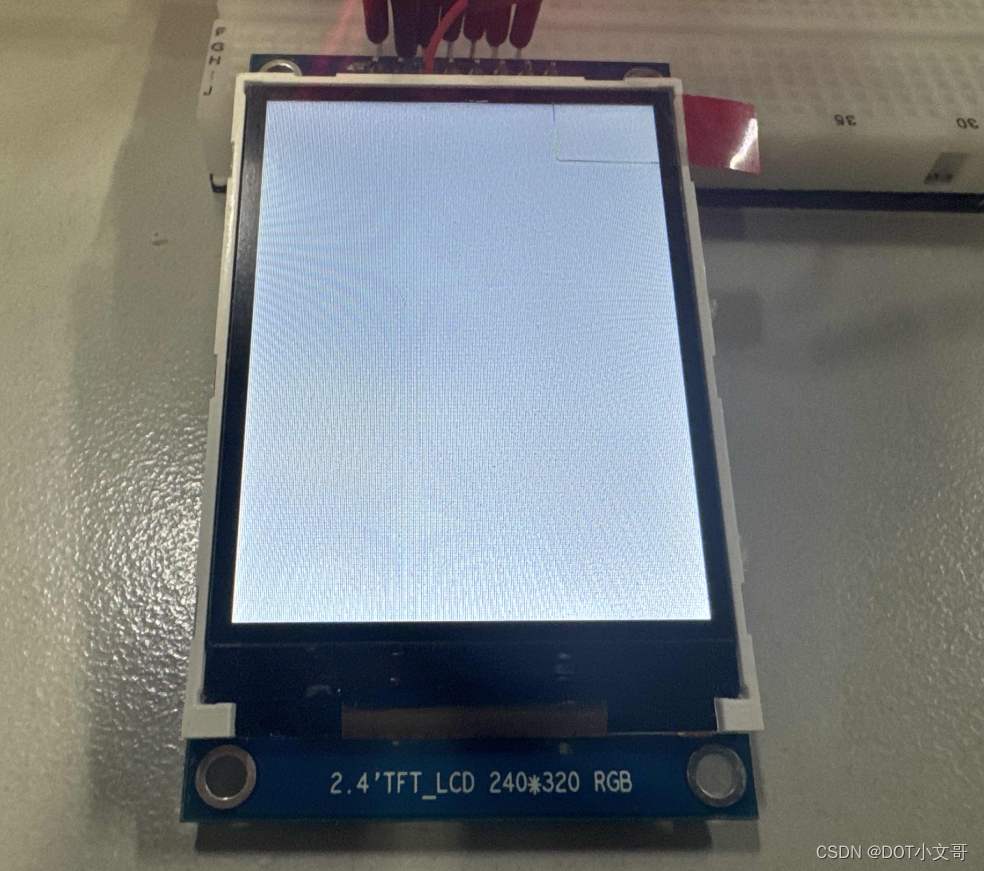

屏幕白屏

屏幕白屏,但是背光亮起

白屏是因为屏幕没有初始化,需要检查屏幕初始化序列或者初始化数据是否正确。

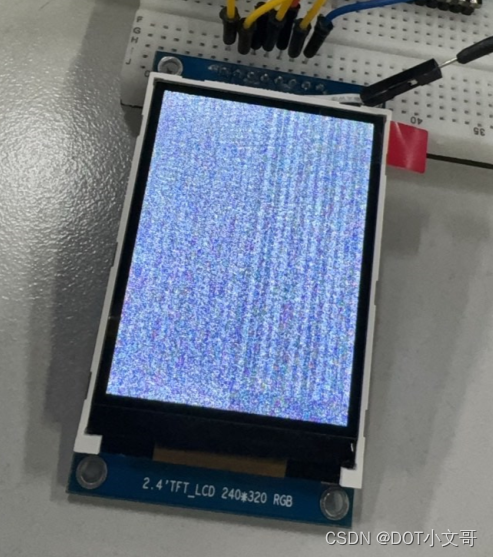

屏幕花屏

屏幕花屏,无法控制

花屏一般是因为屏幕初始化后没有正确设置 addrwin,或者初始化序列错误。

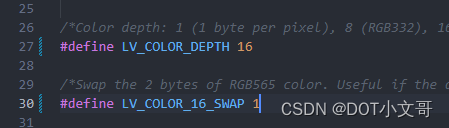

LVGL 屏幕颜色不正确

出现反色,颜色异常

请配置 LVGL LV_COLOR_DEPTH 参数为 16,LV_COLOR_16_SWAP 为 1,这是由 SPI LCD 的特性决定的。

显示反色

运行 test_spilcd ,屏幕显示蓝色。

这是由于屏幕启动了 RB SWAP,一般是 0x36 寄存器修改

正常显示

sunxi_lcd_cmd_write(sel, 0X36);

sunxi_lcd_para_write(sel, 0x00);

反色显示

sunxi_lcd_cmd_write(sel, 0X36);

sunxi_lcd_para_write(sel, 0x08);

/6

/6